Custom Diagnostic Tool for Lottery Terminal Peripherals

In-House Design & Implementation

Company: NCR Canada Ltd.

During a major upgrade project for the Lottery system, we encountered widespread serial communication issues on Keno Displays (LED message boards) after site conversions. The problems stemmed from RS-232 cabling and peripheral connections on thousands of remote Lottery Ticket terminals. Quick, reliable resolution was critical due to the large number of affected sites.

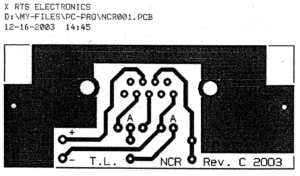

The project required a fully in-house solution: I designed, prototyped, and oversaw the production of a purpose-built RS-232 diagnostic adapter/tool. All components were sourced locally, circuit boards were commercially fabricated, and multiple units were hand-assembled and individually tested. I personally built and iterated through three prototype versions before finalizing the production design.

Key Design Features & Rationale

- Long-distance “cat-and-mouse” architecture — The tool allowed the LED message board to remain up to 100 feet from the terminal, reusing existing building infrastructure cabling. Only the cable ends needed modification, eliminating expensive and disruptive new cable runs.

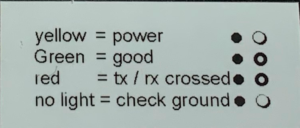

- Extremely simple pass/fail indication — A single multi-color LED provided instant feedback: Green = Good (all connections correct), Red = Bad (fault detected). This was deliberately chosen for field technicians who often lacked deep technical expertise.

- Zero-cost PCB design — The board was created using free/open-source PCB layout software to keep development expenses minimal.

- Comprehensive fault coverage — The device performed several critical checks:

- Verified proper ground connection (the tool would not power on or light up at all if ground was missing or incorrect, preventing false positives).

- Confirmed correct Transmit/Receive line orientation.

- Detected shorts, opens, and crossed pairs in the non-standard cable termination.

- Non-standard connector workaround — The proprietary cable end used in the system was incompatible with commercial cable testers (which were expensive, complex to interpret, and required training). My design replaced reliance on those tools with a single, intuitive, field-friendly device.

Development Context & Impact

Faced with a very tight project deadline, the main upgrade work was temporarily paused while I focused exclusively on designing, prototyping, testing, and producing this custom tool. The entire process—from concept to field-ready units—was completed in approximately two weeks with a cost of about 15 dollars each device.

The result was a robust, low-cost diagnostic solution that dramatically reduced troubleshooting time, minimized site downtime, and ensured consistent, repeatable results across thousands of remote locations. By addressing both the technical communication failures and the human factors (ease of use for non-expert field staff), the tool demonstrated strong attention to end-to-end problem solving, thoughtful hardware design, cost-conscious engineering, and rapid implementation under pressure.

Parts

- 1 x 100 ohm resistor

- 1 x 1 K ohm resistor

- 1 x 2.2 K ohm resistor

- 1 x Dual color LED

- 1 x Yellow LED

- 1 x Green LED

- 1 x Circuit board

- 1 x RJ11 female adapter

- 1 x 9 pin male adapter board mount

- 1 x Hobby Case

- 1 x 9 volt battery